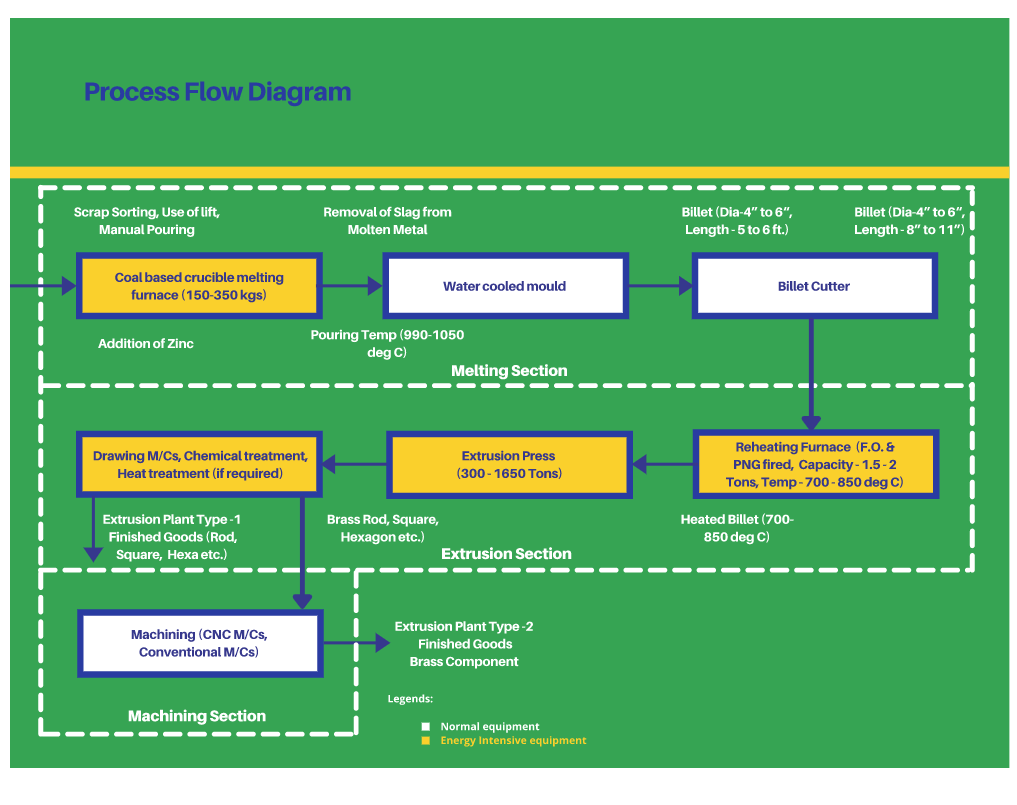

Brass Extrusion process is used to create objects of a fixed Brass cross-sectional profile. brass material is pushed through a die of the related cross-section. The main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms parts with an excellent surface finish.

Brass Extrusion Process & Quality

We are believe in each products should be same quality while delivery to customers, that reason we use quality machine process where step by step check each product batch quality and we provide best quality brass rods and brass bars, Brass round bars products to our customers.

Hardner Tester

Spectro