About

Find Out More About Us

We are leading manufacturer of brass extrusion products.Top 10 Brass Extrusion Manufacturers. we have over 30 years experience in this sector

Abhay Extrustion Provides wide range of brass extrusion

Abhay Extrusion use as many industries compornant row matirials like Automative, electic & electronics, lpg industrial valve, Agriculture equipment, Ball bearing, Surgical equipment, Air creaft componant, home applience, Lock, Hardware, sanitary, Plumbing,Pharmaceutical industries

-

Quality Product

We are commited with our product quality and process in Brass Profile, Brass bars, Brass rods

-

Customize Brass Extrusion

We are provide customized brass extrusion based on client requirements

Our product used in quality brass componant manufacturing process, we are supplier of leading brass componant manufaturing company who always maintain quality it self.

Years Experience

Happy Clients

Types Of Products

Team members

Products

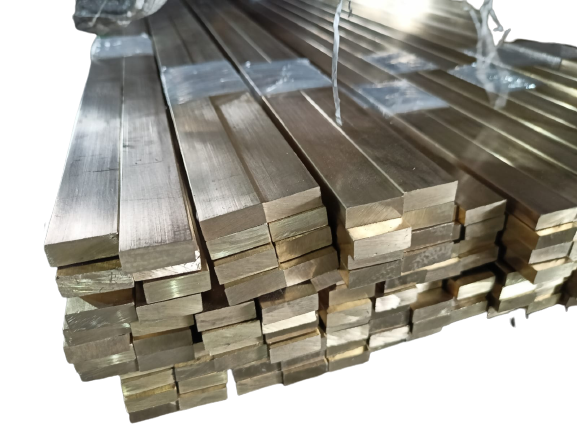

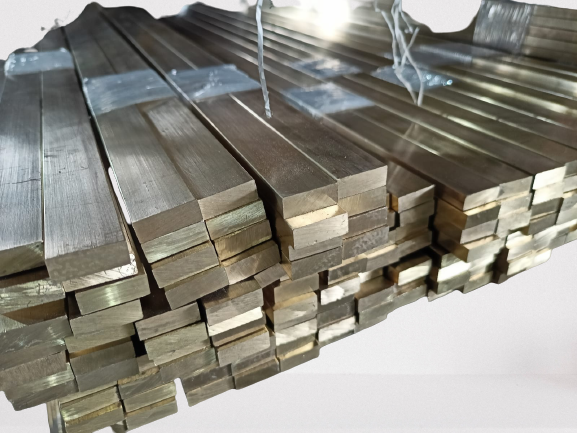

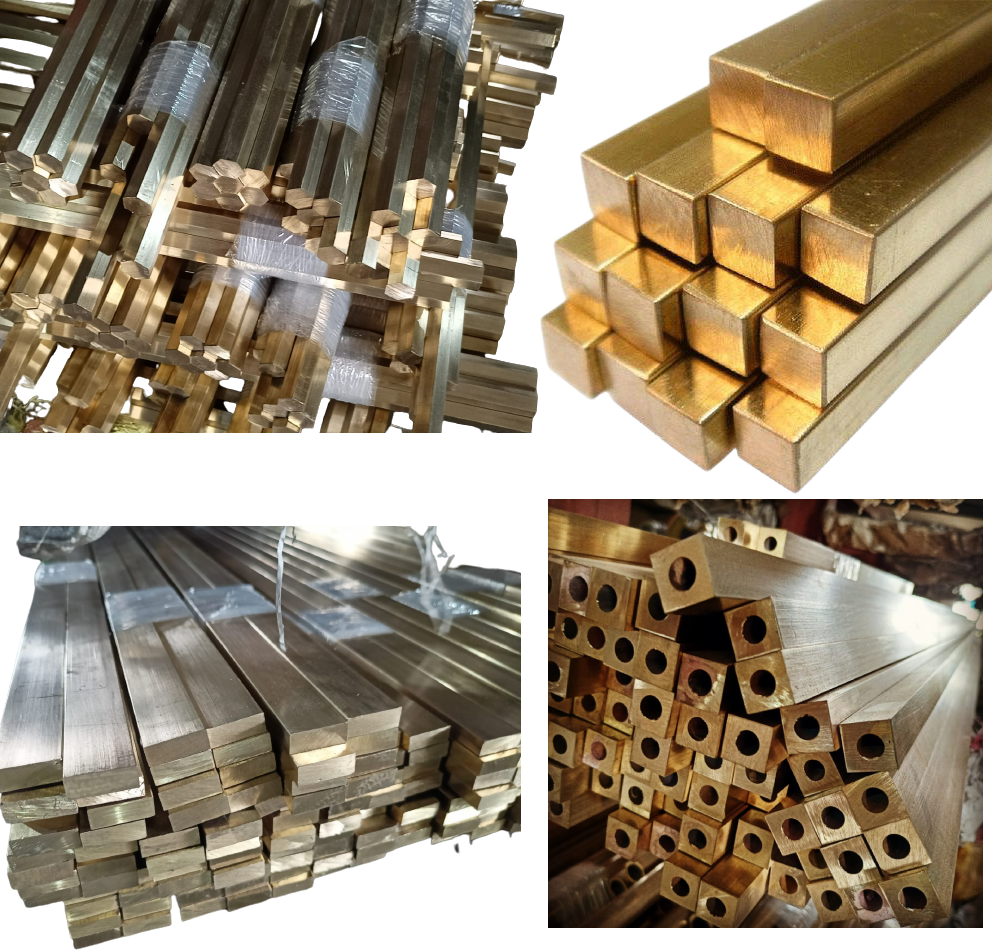

Check our Products

We are manufactiring diffrent types of extrusion based on requirements

- All

- Round Extrusion

- Hex Extrusion

- Square Extrusion

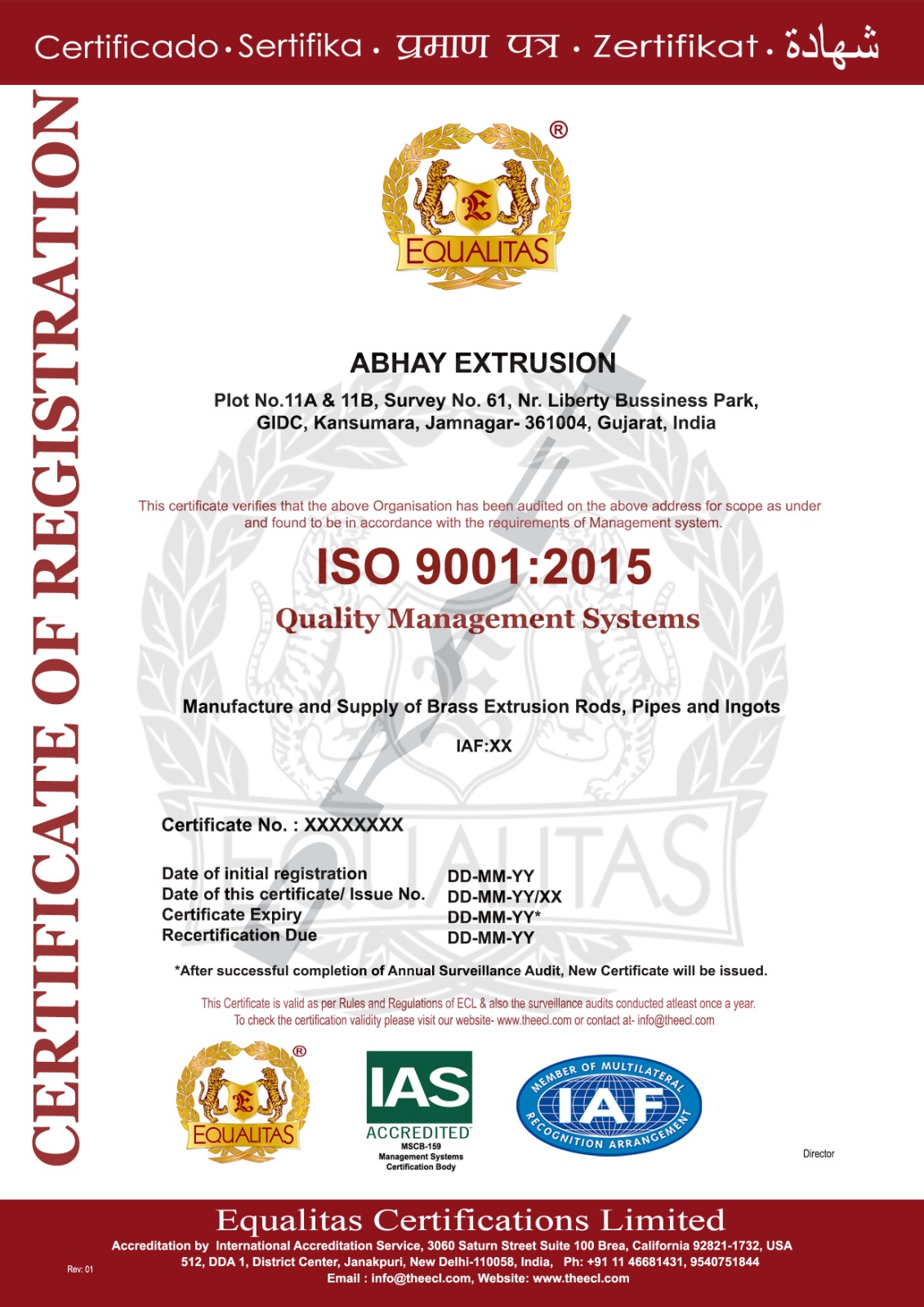

Certificate

F.A.Q

Frequently Asked Questions

Common Asked Question about Products

-

How Can brass be extruded?

Raw metirial Extruded brass is forced through a die using machine to make diffrent shaped brass bars, Round, Hex, Square and rectangular etc. The extrusion process is very similar to meke share from matel forging. By result is long rods or bars that are used as the raw material for diffrent industries.

-

Where use brass extsution?

Brass extrusion are raw materials for brass industries, where different types for brass extrustion are use for develop diffrent product using cnc and vnc machines.

-

How can we use brass extrusion for brass componant ?

Brass rods are in different shapes like round,square, hex , rectangle ,it is use for develop brass components by calculate its shapes.

-

How can We order brass extrusion?

Brass Extrusion use for brass componant,we develop diffrent type of share by clients requirement

Extrusion Process Video

Extrusion Grades

| Chemical Requirements (%) | Grade I |

|---|---|

| Copper |

56.0 - 59.0 % |

| Lead |

2.0 - 3.50 % |

| Iron |

0.35% max. |

| Total Imp. Excl. Iron |

0.70% max. |

| Zinc | Remainder |

| Physical Properties | |||

|---|---|---|---|

| Condition | Size | T. S. MPA | EL % Min |

Annealed (O) |

6-25 | 345 | 12 |

| 25-50 | 315 | 17 | |

| 50 above | 285 | 22 | |

| Half-Hard (HB) | 6-12 | 405 | 4 |

| 12-25 | 395 | 6 | |

| 25-50 | 355 | 12 | |

| Hard (HD) | 50 above | 325 | 17 |

| 6-12 | 550 | - | |

| 12-25 | 490 | 4 | |

| Fabrication Properties | |

|---|---|

| Capacity for being |

|

| Cold worked |

Poor |

| Hot formed |

Fair |

| Machinability Rating |

100% |

| Suitability for Soldering |

Excellent |

| Suitability for Brazing | Good |

IS 319 / 89 NR. EQUIVALENT SPEC. BS 2874 / 86 CZ124, JIS3250 H C-3602, ASTMBC36000

| Chemical Requirements (%) | Grade II | Grade III |

|---|---|---|

| Copper | 60.0 - 63.0 % |

60.0 - 63.0 % |

| Lead |

2.50 - 3.70 % |

0.50 - 1.50 % |

| Iron |

0.35 % max. |

0.20 % max. |

| Total Imp. Excl. Iron |

0.50 % max. |

0.50 % max. |

| Zinc | Remainder | Remainder |

| Physical PropertiesGrade IIGrade III | |||||

|---|---|---|---|---|---|

| Condition | Size | T. S. MPA | EL % Min | T. S. MPA | EL % Min |

| Annealed (O) | 6-25 | 355 | 15 | 315 | 22 |

| 25-50 | 305 | 20 | 285 | 27 | |

| 50 above | 275 | 25 | 255 | 32 | |

| Half-Hard (HB) | 6-12 | 395 | 7 | 355 | 8 |

| 12-25 | 385 | 10 | 345 | 12 | |

| 25-50 | 345 | 15 | 305 | 22 | |

| Hard (HD) | 50 above | 315 | 20 | 285 | 27 |

| 6-12 | 550 | - | 460 | - | |

| 12-25 | 485 | 4 | 400 | 4 | |

| Physical PropertiesGrade IIGrade III | ||

|---|---|---|

| Capacity for being |

||

| Cold worked |

Poor |

Fair |

| Hot formed |

Fair |

Excellent |

| Machinability Rating |

90% |

80% |

| Suitability for Soldering |

Excellent |

Excellent |

| Suitability for Brazing | Good | Excellent |

BS 2874 – CZ 131 NR, EQUIVALENT SPEC. DTD 627, EN CW606N – 12164

DIN CuZn36Pb2 – 17900, UNS – C35300

| Chemical Requirements(%) | |

|---|---|

| Copper | 61.00 - 63.00 % |

| Lead | 1.50 - 2.50 % |

| Iron | - 0.20 % max |

| Total Imp Excl. Iron | - 0.50 % max |

| Zinc | Remainder |

| Physical Properties : (1/2 Hard) | |||

|---|---|---|---|

| Condition | Size | T. S. MPa | EL % Min. |

| Half-Hard (AB) | 6 - 18 | 350 | 22 |

| 18 - 40 | 350 | 25 | |

| 40 - 80 | 350 | 28 | |

| Above 80 mm | 330 | 28 | |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold Worked | Poor |

| Machinability Rating (IS 319-I 100) | 70 |

| Bending | Excellent |

| Cold Heading | Excellent |

| Rivetting | Excellent |

EN 12164 : 1998

| A | B | |

|---|---|---|

| Chemical Requirement(%) |

CuZn39Pb3 | CuZn40Pb2 |

| CW614N | CW617N | |

| Copper | 57 - 59 % | 57-59 % |

| Lead | 2.5 - 3.5 % | 1.6 - 2.5 % |

| Aluminum | 0.05 % max | 0.05 % max |

| Iron | 0.30 % max | 0.30 % max |

| Nickle | 0.30 % max | 0.30 % max |

| Tin | 0.30 % max | 0.30 % max |

| Total Imp. | 0.20 % max | 0.20 % max |

| Zinc | Remainder | Remainder |

| Physical Properties : (1/2 Hard) | ||||||

|---|---|---|---|---|---|---|

| Condition | Size | T. S. MPa | EL % Min. | Size | T. S. MPa | EL % Min. |

| Half-Hard (AB) | 6 -14 | 400 | 15 | 6 -14 | 550 | |

| 14 - 40 | 380 | 18 | 14 - 40 | 500 | 8 | |

| 40 - 80 | 360 | 20 | 40 - 80 | 430 | 10 | |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold Worked | Poor |

| Hot Formed | Excellent |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

BS 218

| Chemical Requirement (%) | |

|---|---|

| Copper | 56.50 - 60.00 % |

| Lead | 1.00 - 2.50 % |

| Iron | 0.30 % max |

| Total Imp. | 0.70 % max |

| Zinc | Remainder |

| Physical Properties | |

|---|---|

| Rm - Tensile strength in Kg / mm2 | 32 min. |

| Elongation on 5.65 A% | 25 min. |

| Fabrication Properties | |

|---|---|

| Capacity for being |

|

| Cold Worked | Poor |

| Hot Formed | Excellent |

| Hot Forgebility Rating (Forging Brass - 100 ) | 100 |

| Machinability Rating (IS 319-I 100) | 80 |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

IS – 6912 / 2005 FLB

| Chemical Requirement (%) | |

|---|---|

| Copper | 56.50 - 60.00 % |

| Lead | 0.60 - 2.00 % |

| Iron | 0.30 % max. |

| Total Imp excl Fe | 0.75 % max |

| Zinc | Remainder |

| Physical Properties | |

|---|---|

| Rm - Tensile strength in Mpa | 310 min. |

| Elongation on 5.65 A% | 25 min. |

| Fabrication Properties | |

|---|---|

| Capacity for being |

|

| Cold Worked | Poor |

| Hot Formed | Excellent |

| Hot Forgebility Rating (Forging Brass - 100 ) | 100 |

| Machinability Rating (IS 319-I 100) | 80 |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

IS 3488 / 80 NR. EQUIVALENT SPEC. BS 2874 / 86 CZ122,ASTMBC37700

| Chemical Requirements (%) | CuZn42Pb2 | CuZn40Pb2 |

|---|---|---|

| Copper | 56.5 - 60.0 % | 57.0 - 59.0 % |

| Lead | 0.60 - 2.0 % | 1.50 - 2.50 % |

| Iron | 0.30 % max. | 0.40 % max. |

| Total Imp. Excl. Iron | 0.20% max | 0.70 % max |

| Zinc | Remainder | Remainder |

| Physical Properties | ||

|---|---|---|

| Tensile Strength | 380 Mpa Min | 40 kg/mm2 min |

| Elongation % | 25% Min | 18% Min. |

| Izod Value | - | 2.0 KJ Min. |

| Fabrication Properties | ||

|---|---|---|

| Capacity for being | ||

| Cold worked | Poor | Poor |

| Hot formed | Excellent | Excellent |

| Hot forgeability Rating | 100% | 100% |

| Machinability Rating | 80% | 80% |

| Suitability for Soldering | Excellent | Excellent |

| Suitability for Brazing | Good | Good |

IS 8737 / AMD – 2

| Chemical Requirements % | |

|---|---|

| Copper | 56.5 - 60.0 % |

| Lead | 1.0 - 2.0 % |

| Manganese | 0.50 % max. |

| Iron | 0.30 % max. |

| Total Imp. | 0.75% max. |

| Zinc | Remainder |

| Physical Properties | |

|---|---|

| Tensile Strength | 40 kg/mm2 Min |

| Elongation % | 18% Min. |

| Izod Value | 2.2 Kgf Min. |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold worked | Poor |

| Hot formed | Excellent |

| Hot forgeability Rating | 100% |

| Machinability Rating | 80% |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

IS 4170 / 67 NR. EQUIVALENT SPEC. BS 2874 / 86 CZ 109,

JIS3250H C-2800, ASTMBC36500

| Chemical Requirements % | CuZn40 |

|---|---|

| Copper | 59.0 - 62.0 % |

| Lead | 0.75 % max. |

| Iron | 0.10% max. |

| Total Imp. Excl. Iron | 0.30 % max. |

| Zinc | Remainder |

| Physical Properties | |

|---|---|

| Tensile Strength | 40 kg/mm2 Min |

| Elongation % | 18% Min. |

| Izod Value | 2.2 Kgf Min. |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Machinability Rating | 55 % |

| Bending | Excellent |

| Riveting | Excellent |

| Forging | Excellent |

IS 4413 / 81 NR. EQUIVALENT SPEC. BS 2872 / 86 CZ 108

| Chemical Requirements % | CuZn37 | CuZn30 |

|---|---|---|

| Copper | 62.0 - 65.0 % | 60.5 - 71.50 % |

| Lead | 0.30 % max. | 0.05 % max. |

| Iron | 0.10 % max. | 0.05 % max. |

| Total Imp. | 0.60 % max. | 0.30 % max. |

| Zinc | Remainder | Remainder |

| Physical Properties | ||||

|---|---|---|---|---|

| Condition | T. S. MPa | EL % Min | T. S. MPa | EL % Min |

| Annealed (O) | 325 min | 35 % | 315 min | 45 % |

| Half-Hard (HB) | 460-620 | - | 460-620 | - |

| Hard (HD) | 660-775 | - | 620 min | - |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Machinability Rating | 40 % |

| Bending | Excellent |

| Riveting | Excellent |

| Forging | Excellent |

IS 2704 / 83 NR. EQUIVALENT SPEC. BS 2874 CZ 119

JIS3250 H C-2700, ASTMBC34000

| Chemical Requirements % | CuZn35Pb1 | CuZn35 |

|---|---|---|

| Copper | 62.0 - 65.0 % | 63.0 - 68.0 % |

| Lead | 0.75 - 1.50 % | 0.02 % max. |

| Iron | 0.10 % max. | 0.05 % max. |

| Total Imp. | 0.50 % max. | 0.30 % max. |

| Zinc | Remainder | Remainder |

| Physical Properties | ||||

|---|---|---|---|---|

| Condition | T. S. MPa | EL % Min | T. S. MPa | EL % Min |

| Quarter Hard (HA) | 325-390 | 30% | 340-345 | 30% |

| Half-Hard (HB) | 400-490 | 20% | 420-510 | 15% |

| Hard (HD) | 500-685 | 15% | - | - |

| Extra Hard (HE) | 695-885 | 5% | - | - |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold Forming | Excellent |

| Machinability Rating | 70 % |

| Bending | Excellent |

| Riveting | Excellent |

IS 320 / 80 NR. EQUIVALENT SPEC. BS 2874 CZ 114 & CZ 115,

JIS3250H C6782 & C6783

| Chemical Requirements % | HT1 | HT2 |

|---|---|---|

| Copper | 56.0 - 60.0 % | 56.0 - 61.0 % |

| Lead | 0.20 - 1.50 % | 0.50 - 1.50 % |

| Iron | 0.20 - 1.25 % | 0.20 - 1.50 % |

| Tin | 0.20 - 1.0 % | 1.0 % max |

| Aluminum | 0.20 % max. | 0.30 - 2.0 % |

| Manganese | 0.25 % - 2.0 % | 0.50 - 2.0 % |

| Total Imp. | 0.50 % max. | 0.50 % max. |

| Zinc | Remainder | Remainder |

| Physical Properties | |||||

|---|---|---|---|---|---|

| Condition | Size | T. S. Mpa | EL % Min | T. S. Mpa | EL % Min |

| As manufactured | All Size | 430 min | 20 % | 460 min | 20 % |

| Cold worked & Stress | 10-40 | 480 min | 12 % | 520 min | 12 % |

| Relieved | 40 above | 500 min | 15 % | ||

| Fabrication Properties | ||

|---|---|---|

| Capacity for being | ||

| Cold Formed | Poor | Fair |

| Hot Worked | Good | Good |

| Machinability Rating | 30 % | 30% |

| Resistance to Corrosion | Excellent | Excellent |

| Suitability for Soldering | Excellent | Fair |

IS 291 / 89 NR. EQUIVALENT SPEC. BS 2874 CZ 112, CZ 113,

JIS3250 H C4622 / 41, ASTMBC482 / 8500

| Chemical Requirements % | Grade I | Grade II |

|---|---|---|

| Copper | 61.0 - 64.0 % | 59.0 - 62.0 % |

| Lead | 0.20% max. | 0.50 - 1.0 % |

| Tin | 1.0 - 1.50 % | 0.50 - 1.0 % |

| Iron | 0.10 max. | - |

| Total Imp. | 0.20 max. | 0.20 % max. |

| Zinc | Remainder | Remainder |

| Physical Properties | |||||

|---|---|---|---|---|---|

| Condition | Size | T. S. kg/mm2 | EL % Min | T. S. kg/mm2 | EL % Min |

| Half-Hard (HB) | Upto 12.5 | 40 min | 18 % | 40 min | 15% |

| 12.5 to 50 | 38.5 min | 18 % | 40 min | 15% | |

| 50 to 100 | 35 min | 18 % | 40 min | 15% | |

| Fabrication Properties | ||

|---|---|---|

| Capacity for being | ||

| Cold Worked | Fair | Poor |

| Hot Worked | Excellent | Good |

| Machinability Rating | 30% | 50% |

| Forgeability Rating | 90% | 90% |

| Silver Alloy Brazing | Excellent | Good |

| Soft Soldering | Excellent | Excellent |

| Oxyacetylene Welding | Good | Not Suitable |

| Standard Specification | CW602N |

|---|---|

| (A) Chemical Requirements % | Europe |

| Copper | 61.0 - 63.0 % |

| Lead | 1.70 - 2.8 % |

| Aluminum | 0.05 % max. |

| Nickel | 0.30 % max. |

| Iron | 0.10 % max. |

| Tin | 0.10 % max. |

| Zinc | Remainder |

| Total Impurities | 0.20 % max. |

| Arsenic | 0.02 - 0.15 % |

| Remarks : | Mn <=0.1 |

| (B) Mechanical Properties | |

| Ultimate Tensile Strength MPa | 430 min. |

| Elongation MPa | 200 min. |

| Hardness HB | 110 min. |

IS 8328 / 77

| Chemical Requirements % | |

|---|---|

| Copper + Ag | 99.90 % min |

| Lead | 0.8 - 1.5 % |

| Physical Properties | ||

|---|---|---|

| Condition | T. S. MPa | EL % Min |

| Half-Hard (HB) | 260 | 12 % |

| Fabrication Properties | |

|---|---|

| Capacity for being Cold Worked | Good |

| Hot Worked | Poor |

| Machiniability Rating | 80% |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

| Electrical Conductivity | 85% IACS |

BS 2874 CZ 130, EN 12167, CW 624 N

| Chemical Requirement (%) | |

|---|---|

| Copper | 55.50 - 57.50 % |

| Lead | 2.50 - 3.50 % |

| Aluminum | 0.50 % max. |

| Total Imp. | 0.70 % max. |

| Zinc | Remainder |

| Physical Properties : | |

|---|---|

| Rm - Tensile strength in Mpa | 370 min. |

| Elongation on 5.65 A% | 25 min. |

| Proof strees (0.20%) in Kg/mm2 | 160 min. |

| Hardness (HV) | 90-120 |

| Fabrication Properties : | |

|---|---|

| Machinability Rating (IS 319-l 100) | 100 |

IS 288 / 81

| Chemical Requirements % | |

|---|---|

| Copper + Silver | 99.20 % min |

| Arsenic | 0.20 - 16.50 % |

| Antimony | 0.05 % max. |

| Bismuth | 0.002 % max. |

| Oxygen | 0.10 % max |

| Lead | 0.01 % max |

| Physical Properties | |||

|---|---|---|---|

| Condition | Size | T. S. MPa | EL % Min |

| Annealed | 10 to 25 | 215 | 35% |

| 25 to 50 | 205 | 40% | |

| 50 & above | 195 | 40% | |

| As Manufactured | 10 to 25 | 255 | 15% |

| 25 to 50 | 245 | 18% | |

| 50 & above | 235 | 20% | |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold Worked | Excellent |

| Hot Formed | Excellent |

| Suitability for Soldering | Good |

| Suitability for Brazing | Good |

| Suitability for Riveting | Excellent |

IS 10569 / 05 NR. EQUIVALENT SPEC. ASTMBC64200

| Chemical Requirements % | CuAl7Si2 |

|---|---|

| Copper | Remainder |

| Aluminum | 6.3 - 7.60 % |

| Iron | 0.30 % max. |

| Nickel | 0.25 % max. |

| Manganese | 0.10 % max. |

| Tin | 0.20 % max. |

| Lead | 0.05 % max. |

| Zinc | 0.50 % max. |

| Silicon | 1.5 - 2.2 % |

| Total Imp. Excl. Fe, Ni & Mn | 0.50 % max. |

| Physical Properties | |||

|---|---|---|---|

| Condition | Size | T. S. Kg/mm2 | EL % Min |

| Annealed / As Manufactured | 6 to 15 | 620 | 9% |

| 15 to 50 | 575 | 12% | |

| 50 to 80 | 515 | 12% | |

| 80 & above | 485 | 15% | |

| Fabrication Properties | |

|---|---|

| Capacity for being | |

| Cold Worked | Not Suitable |

| Hot Formed | Excellent |

| Machiniability Rating | 80% |

| Suitability for Soldering | Excellent |

| Suitability for Brazing | Good |

Extrusion Grades

WEIGHT ROD WEIGHT CHART

| ROUND | ROUND | ROUND |

|

HEX | HEX | HEX | SQUARE |

|---|---|---|---|---|---|---|---|

|

5.90/5.95 |

18.55 |

30.25 |

|

7.00 |

20.50 |

30.05 RC |

5.95 |

|

6.25 |

19.00 |

31.00 |

|

7.80 |

21.00 |

30.40 RC |

7.84 |

|

6.40 |

19.50 |

32.00 |

|

7.85 |

22.00 |

30.50*32.50 |

8.00 |

|

6.90/7.00 |

20.00 |

32.50 |

|

8.90 |

22.00*24.70 |

31.00 |

9.45 |

|

7.15 |

21.00 |

33.15 |

|

9.00 |

22.20 |

31.75 |

9.90*12.70 |

|

7.40 |

21.30 |

34.00 |

|

9.50 |

22.00*25.00 |

31.75*35.60 |

10.50 RC |

|

7.80 |

21.50 |

34.50 |

|

9.80 |

22.30 RC |

32.00 |

12.00 |

|

7.90/7.95 |

21.80 |

35.00 |

|

9.85 |

22.35*24.90 |

32.00 RC |

13.00 RC |

|

8.00 |

22.00 |

35.20 |

|

10.00 |

22.80 |

32.00*35.00 |

15.00 |

|

8.10 |

22.10 |

36.00 |

|

11.00 |

23.00 |

32.00*35.70 |

18.00 |

|

8.80 |

22.22 |

37.00 |

|

12.00 |

23.80*26.90 |

32.00*36.35 |

19.00 |

|

8.90 |

22.50 |

38.00 |

|

12.50 |

23.80 FC |

33.00 |

20.00 |

|

9.00 |

22.72 |

40.00 |

|

12.70 |

24.00 |

33.20*36.00 |

26.00 RC |

|

9.50 |

23.00 |

41.00 |

|

12.70 RC |

24.00*25.50 |

34.00 |

28.00 RC |

|

10.20 |

23.70 |

47.00 |

|

13.00 |

25.40 FC |

34.93 RC |

|

|

10.65 |

23.75 |

48.00 |

|

14.00 |

25.40 RC |

35.00 |

6.80*6.32 |

|

11.00 |

24.00 |

49.90 |

|

14.25 RC |

26.20 RC |

36.00 |

25.00*8.60 |

|

11.20 |

24.50 |

|

|

15.00 |

26.00 |

37.50*39.80 |

30.40*14.38 |

|

11.80 |

24.90/25.00 |

|

|

15.87 RC |

26.92 RC |

38.10 |

31.75*6.50 |

|

12.00 |

25.40 |

|

|

16.00 |

27.00 |

41.00 |

45.00*11.70 |

|

12.20 |

26.00 |

|

|

17.00 |

27.20 RC |

45.00 |

47.00*13.70 |

|

12.40 |

26.10 |

|

|

17.20 |

28.00 |

46.00 |

|

|

12.60 |

26.70 |

|

|

17.40 |

28.58 RC |

50.00 |

|

|

12.70 |

27.00 |

|

|

17.46 RC |

28.58 FC |

50.70 |

|

|

12.80 |

28.00 |

|

|

18.00 |

28.80 RC |

54.00 |

|

|

13.00 |

28.90 |

|

|

19.00 RC |

28.80 FC |

55.00 |

20.60*31.75*10.60 |

|

13.20 |

29.15 |

|

|

19.00 |

29.00 |

|

22.08*24.00 |

|

13.70 |

30.00 |

|

|

20.00 |

30.00 |

|

22.55*21.58 |

|

14.00 |

|

|

|

|

30.00*32.70 |

|

22.70*12.75*18.20 |

|

14.25 |

|

|

|

|

30.00*32.10 |

SECTION |

22.50*25.26 |

|

14.50 |

|

|

|

|

|

|

23.14*27.50 |

|

15.00 |

|

NEWSQ |

|

FLATS |

|

|

36.85*31.70 |

|

15.50 |

|

|

|

|

T&B |

44.50*14 |

32.90*25.50*14.50 |

|

15.85 |

|

14.00 |

|

14*44.50 |

|

45.00*15.00 |

32.25*32.25*18.00 |

|

16.00 |

|

21.00 |

|

38.00*6.00 |

55.40*40.40 |

31.50*9.00 |

43.45*25.40*22.30 |

|

16.15 |

|

22.00 |

|

45*15 |

59.65*40.40 |

37.00*15.50 |

|

|

16.50 |

|

25.00 |

|

25.50*13 |

31.75*17.50 |

47.60*19.00 |

21.50*18*14.30 |

|

17.00 |

|

35.00 |

|

25.50*16 |

28*15.90 |

32.75*10.00 |

16*18*17 |

|

17.50 |

|

|

|

9.60*24.80 |

13.50*14.00 |

12.60*19.60 |

31.75*28 |

|

18.00 |

|

|

|

9.60*23.50 |

17.50*18.50 |

40.00*14.90 |

|

|

18.10 |

|

|

|

12.50*25.50 |

20.60*21.10 |

14.00*9.00 |

|

|

18.50 |

|

|

|

12.30*6.30 |

|

13.80*20 |

|

|

|

|

|

|

38.00*6.00 |

|

13.80*26 |

|

Abhay Extrusion Support Team

Typically replies within an hour

I will be back soon

It’s your friend Dany Williams. How can I help you?